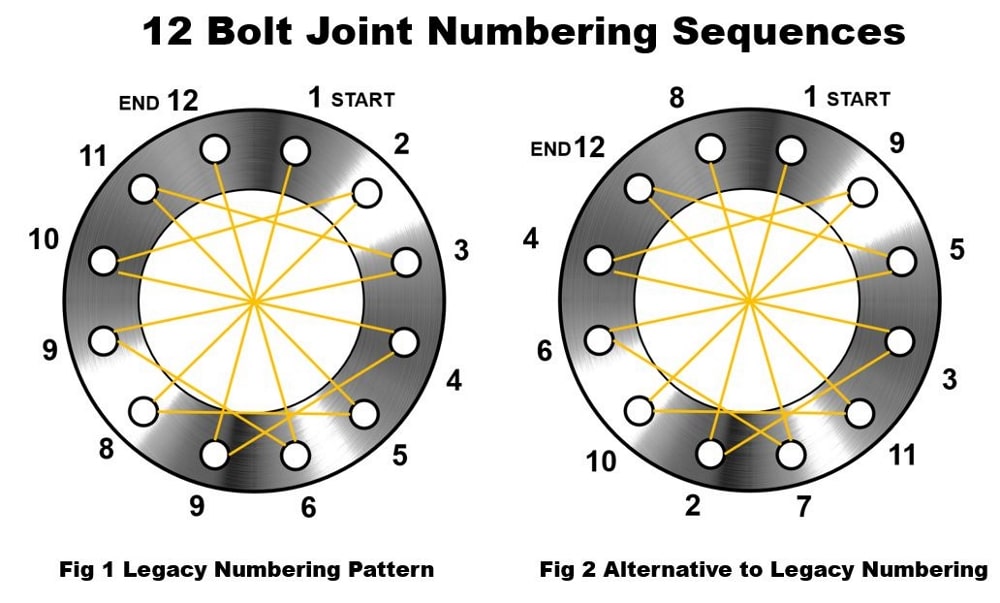

12 Bolt Flange Torque Pattern

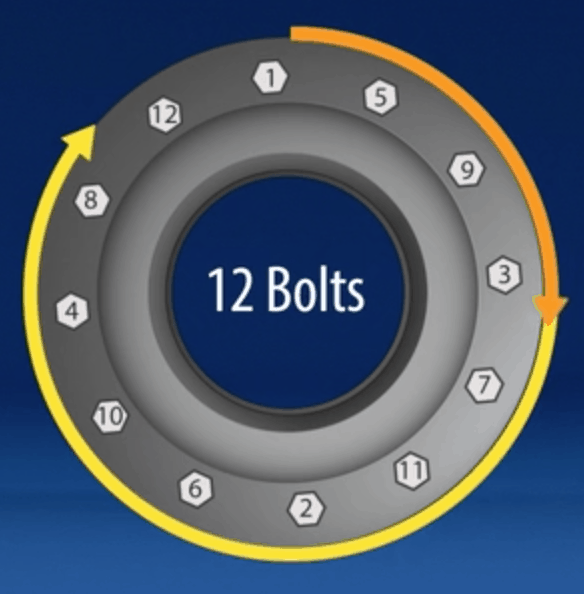

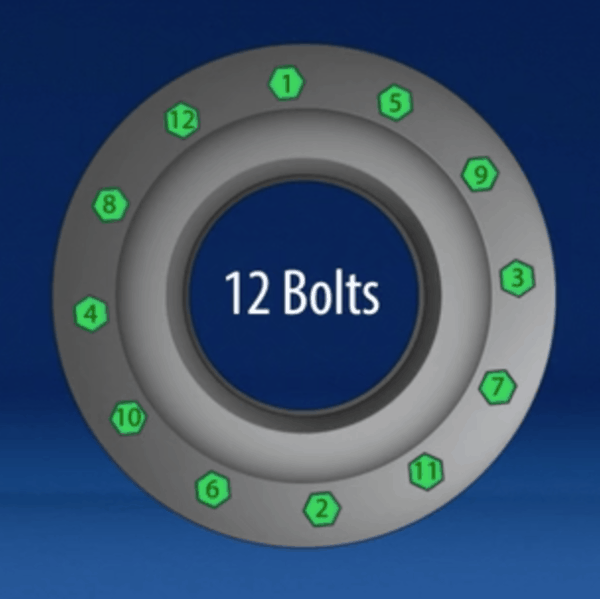

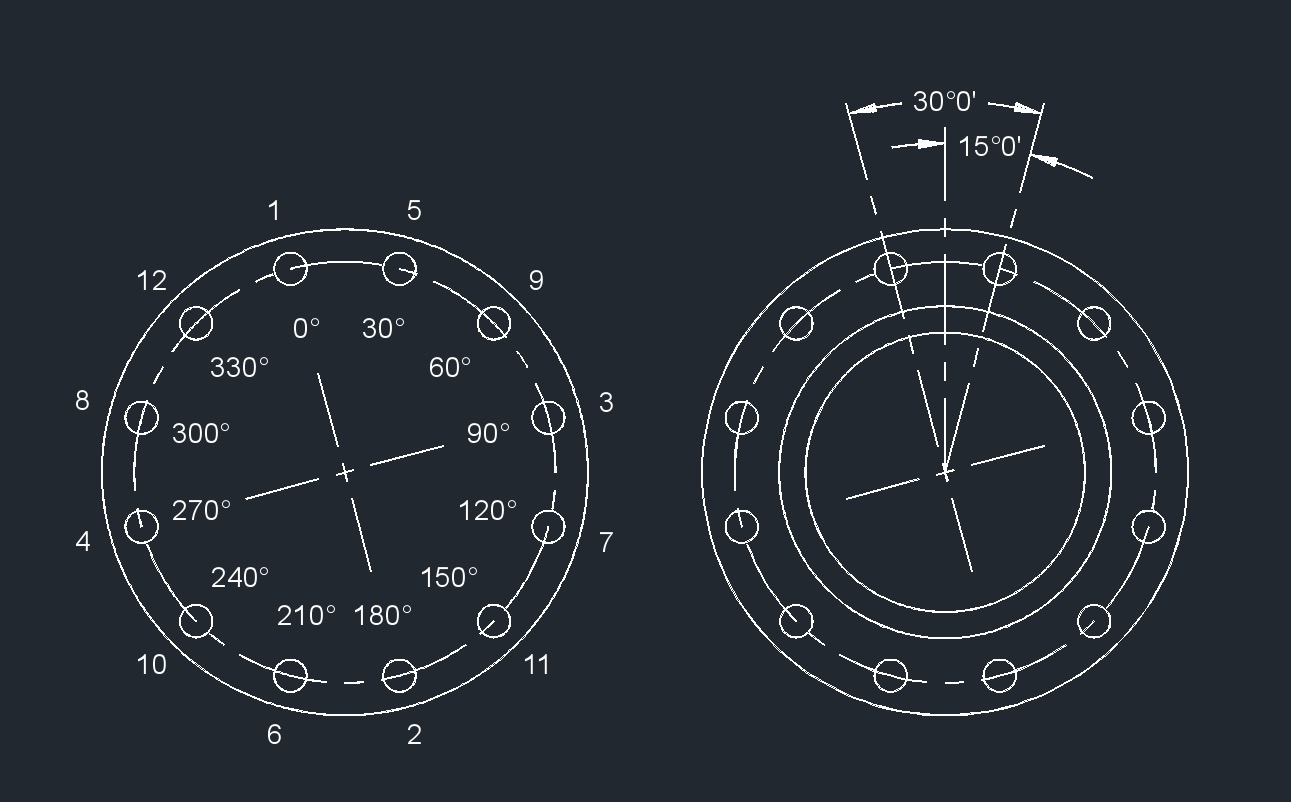

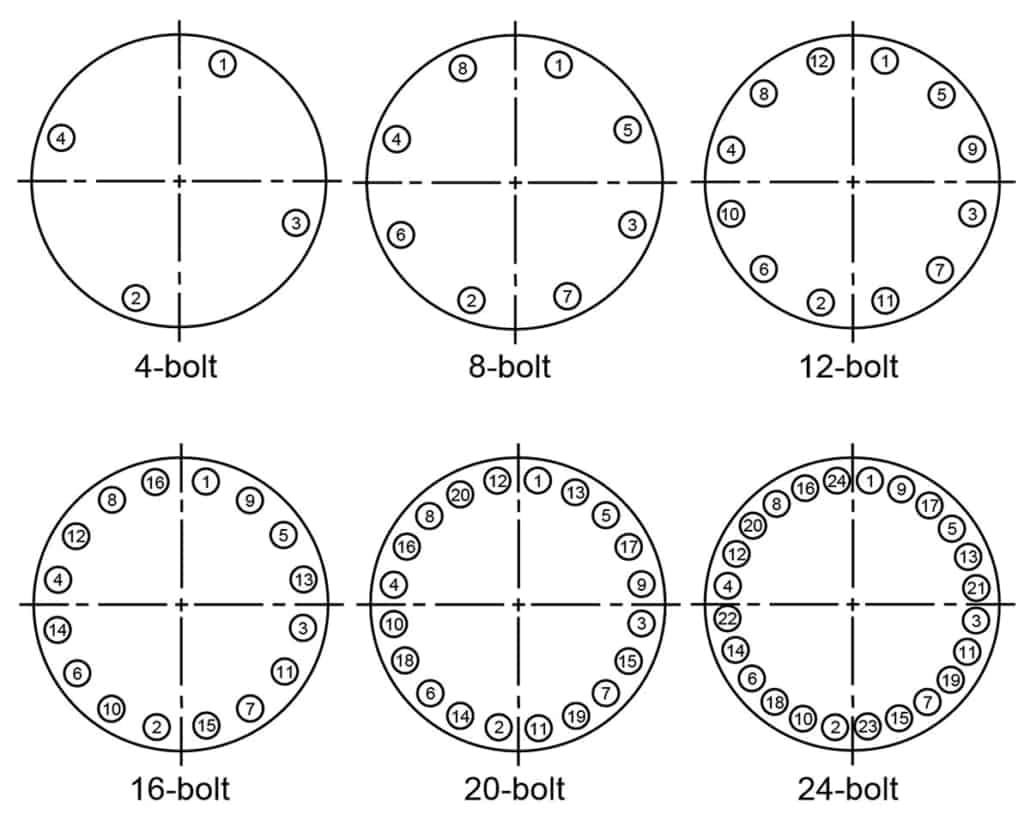

12 Bolt Flange Torque Pattern - Web the flange bolt torque calculator simplifies the task of determining the correct torque for flange bolt tightening, helping to ensure the integrity and safety of critical connections in various industries. The torque tables are built on specific assumptions regarding bolt and nut factor. All moser 12 bolt housings are designed and manufactured in the u.s.a. This torque creates an axial force in the bolt. Tighten to 20% to 30% of target torque usind cross pattern. Competitive prices!all material gradespayment options availablecustom orders available Using moser engineering owned casting boxes. Web flange bolting torque table. 1, 9, 5, 3, 11, 7, 2, 10, 6, 4, 12, 8. Bolt torque is the twisting or turning force applied to tighten the nut on a bolt. Bolt torque is the twisting or turning force applied to tighten the nut on a bolt. Web ansi 150# flanges ansi 300# flanges ansi 600# flanges. If you want to change the stall speed or need any other custom changes just ask. Flange bolt torque sequence for proper gasket installation. The clamp load produced during tightening is. Web flange torque charts listed by nps and by flange class. Web bolt tightening sequence, or torque sequence, is defined in the torque tightening procedure. This torque creates an axial force in the bolt. Web the flange bolt torque calculator simplifies the task of determining the correct torque for flange bolt tightening, helping to ensure the integrity and safety of critical connections in various industries. Check flange gap around circumference for uniformity. Recommended torque values lubricated stud bolts w/0.15 friction value. Web torque pattern for 12 bolt flanges. We have thousands of torque converters in stock and ready to ship. Pivot to resist stress that would bend or break an eyebolt when lifting at an angle. Uip supplies gaskets of all types & sizes for many industrial applications. Continue tightening the bolts, but on a circular clockwise pattern until no Web garlock sealing technologies an enpro industries company. Flange bolt torque sequence for proper gasket installation. Web a complete torque tightening sequence with charts for class 150 to 2500 flanges. Web conventional way to achieve that load is by applying a measured torque to the flange bolts. Using a calibrated torque wrench (manual or hydraulic torque wrench), flange bolt torque can be measured during flange assembly. Flange bolt torque sequence for proper gasket installation. Flange joints are torqued tight with the help of a torque wrench (manual or hydraulic). Web flange bolting torque table. Web torque pattern for 12 bolt flanges. Web flange bolt torque calculation formula. Web bolt tightening sequence, or torque sequence, is defined in the torque tightening procedure. Web flange bolting torque table. Housing, with oem located mounting provisions, seamless steel tubing (3 o.d., 1/4 wall), custom alloy axles (30,. Recommended torque values lubricated stud bolts w/0.15 friction value. Web the flange bolt torque calculator simplifies the task of determining the correct torque for flange bolt tightening, helping to ensure the integrity and safety of critical connections in various industries. In this article, you will learn about the torque sequence of pipe flanges. Web flange torque charts listed by nps and by flange class. Web to calculate the flange. Tighten to 50% to 70% of target torque usind cross pattern. Web the flange bolt torque calculator simplifies the task of determining the correct torque for flange bolt tightening, helping to ensure the integrity and safety of critical connections in various industries. Flange joints are torqued tight with the help of a torque wrench (manual or hydraulic). Web control the. Web flange torque charts listed by nps and by flange class. Tighten to 50% to 70% of target torque usind cross pattern. Check flange gap around circumference for uniformity. Web conventional way to achieve that load is by applying a measured torque to the flange bolts. Before using a given torque table, these assumptions should be verified to insure they. Uip supplies gaskets of all types & sizes for many industrial applications. In this article, you will learn about the torque sequence of pipe flanges. Web to calculate the flange bolt torque, multiply the tightening factor by the axial force and the diameter, then divide by 12. Competitive prices!all material gradespayment options availablecustom orders available Web flange torque charts listed. Tighten to 20% to 30% of target torque usind cross pattern. Tighten to 100% of target torque usind cross pattern. Web the flange bolt torque calculator simplifies the task of determining the correct torque for flange bolt tightening, helping to ensure the integrity and safety of critical connections in various industries. Uip supplies gaskets of all types & sizes for. Using a calibrated torque wrench (manual or hydraulic torque wrench), flange bolt torque can be measured during flange assembly. Pivot to resist stress that would bend or break an eyebolt when lifting at an angle. Asme advise that potential gasket damage or flange misalignment should be considered when bolts are grouped. Web flange bolting torque table. 1, 9, 5, 3,. Web instant flange bolt sizes and torque patterns: If you want to change the stall speed or need any other custom changes just ask. In this article, you will learn about the torque sequence of pipe flanges. Web bolt tightening sequence, or torque sequence, is defined in the torque tightening procedure. This torque creates an axial force in the bolt. Continue tightening the bolts, but on a circular clockwise pattern until no Competitive prices!all material gradespayment options availablecustom orders available Pivot to resist stress that would bend or break an eyebolt when lifting at an angle. Bolt torque is the twisting or turning force applied to tighten the nut on a bolt. Housing, with oem located mounting provisions, seamless steel tubing (3 o.d., 1/4 wall), custom alloy axles (30,. Nominal quantity bolt nominal quantity bolt nominal quantity bolt pipe size of bolts diameter min max pipe size of bolts diameter min max pipe. Web torque pattern for 12 bolt flanges. Web to calculate the flange bolt torque, multiply the tightening factor by the axial force and the diameter, then divide by 12. The torque tables are built on specific assumptions regarding bolt and nut factor. Tighten to 100% of target torque usind cross pattern. Web flange torque charts listed by nps and by flange class.Flange Bolt Tightening Sequence

Flange Bolt Torque Sequence and Torque Table A Complete Bolt

12 Bolt Flange Torque Pattern PDF

Bolt Tightening Sequence and Restrictions Hex Technology

Torque Charts Industrial Bolting and Torque Tools

Pipe Flange Bolt Torque Chart

Flange Bolt Torque Sequence UIP International Premium Industrial

FlangeBoltingPatterns Industrial Bolting and Torque Tools

Bolt Tightening Sequence Why it Matters Enerpac Blog

12 Bolt Torque Pattern

Garlock Sealing Technologies An Enpro Industries Company.

Web Flange Bolting Torque Table.

Uip Supplies Gaskets Of All Types & Sizes For Many Industrial Applications.

Flange Bolt Torque Sequence For Proper Gasket Installation.

Related Post: