Star Pattern Lug Nuts

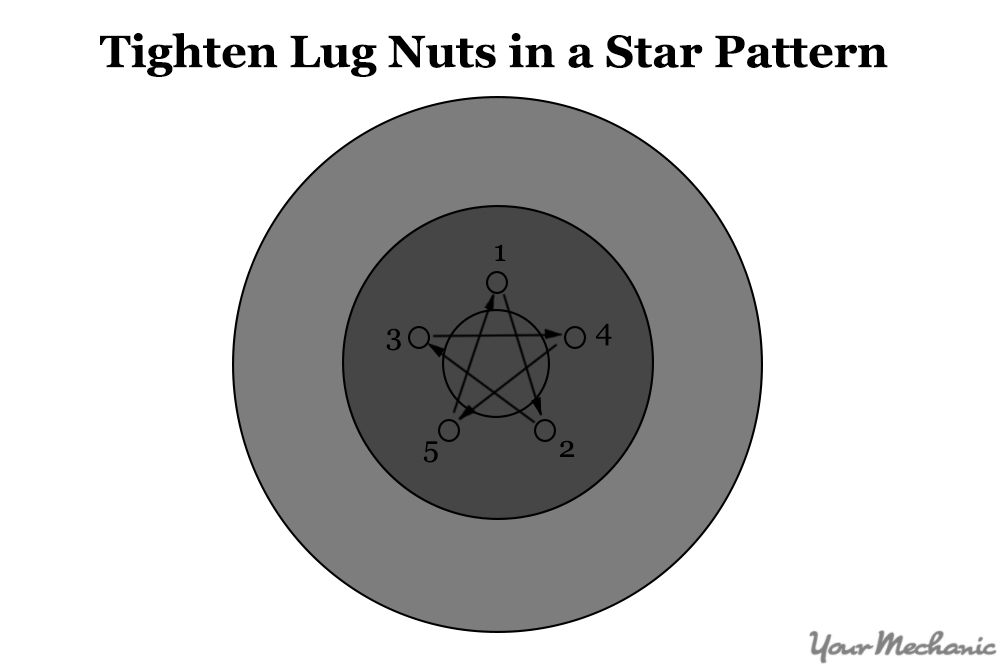

Star Pattern Lug Nuts - This ensures even clamping force. Measure your pattern correctly the first time! Web the vehicle is lowered off of the jack stands till the wheel just touches the ground and torque the lug nuts to specifications in a star pattern. Web you need to tighten your lug nuts in the correct order to achieve proper lug nut torque values. Web start to screw on the lug nuts by hand and note if there is any resistance. Knowing how to tighten lug nuts properly is critical. This ensures a uniform distribution of load across the wheel mounting surface. This diagram will show you what order to tighten your lug nuts. Web here's the secret: Web it’s crucial to tighten lug nuts in a star pattern (moving to the lug nut across from the one you just tightened) to ensure even pressure. Time takes its toll on your. The simple reason behind the star pattern of torquing your lug nuts is to reduce wheel flexing and shifting. Tighten them in a star pattern if possible, meaning tighten one nut, then do one on the opposite. A) thread on corksport extended lug nuts by hand. This pattern is essential for evenly. Web find a locking lug nut replacement key socket using these images of a star point, spline drive or mcguard style wheel lock. This ensures even clamping force. By tightening in a star pattern,. Web here's the secret: Buy p.c.d gauge bolt pattern measuring tool. Web here's the secret: Web you need to tighten your lug nuts in the correct order to achieve proper lug nut torque values. Today, it is throw the tire and wheel over the lugs, hand. Tighten them in a star pattern if possible, meaning tighten one nut, then do one on the opposite. B) using a ratchet and 19mm deep. Web one is the main part that is steel, and the other is a chrome, aluminum, or stainless steel cap that fits on top and makes it look pretty. This ensures a uniform distribution of load across the wheel mounting surface. But as with most car components, there are subtleties involved. This ensures even clamping force. Using the star patter. Web one is the main part that is steel, and the other is a chrome, aluminum, or stainless steel cap that fits on top and makes it look pretty. By tightening in a star pattern,. Refer to the torque chart and use a torque stick if available. Knowing how to tighten lug nuts properly is critical. Web tightening wheel locks. Web how to measure a wheel bolt pattern. Web 4.0 19 ratings. Web tighten one lug nut, then move to the one across from it in a crisscross or star pattern. But as with most car components, there are subtleties involved. Web start to screw on the lug nuts by hand and note if there is any resistance. You see when you tighten a single nut,. But as with most car components, there are subtleties involved. Web how to measure a wheel bolt pattern. Use the torque wrench : However, it’s important to note that over. Web you need to tighten your lug nuts in the correct order to achieve proper lug nut torque values. Web c) remove the factory lug nuts. But as with most car components, there are subtleties involved. Web here's the secret: Web a lug nut tightening pattern, also known as a “star pattern,” is the order in which you should tighten. Web c) remove the factory lug nuts. This pattern helps keep the wheel. Using the star patter as. A) thread on corksport extended lug nuts by hand. 8 point star pattern tuner lug nut key. However, it’s important to note that over. Web start to screw on the lug nuts by hand and note if there is any resistance. Web c) remove the factory lug nuts. Web one is the main part that is steel, and the other is a chrome, aluminum, or stainless steel cap that fits on top and makes it look pretty.. Web find a locking lug nut replacement key socket using these images of a star point, spline drive or mcguard style wheel lock. Using the star patter as. This ensures a uniform distribution of load across the wheel mounting surface. But as with most car components, there are subtleties involved. Web start to screw on the lug nuts by hand. Buy p.c.d gauge bolt pattern measuring tool. Web it’s crucial to tighten lug nuts in a star pattern (moving to the lug nut across from the one you just tightened) to ensure even pressure. A) thread on corksport extended lug nuts by hand. Tighten them in a star pattern if possible, meaning tighten one nut, then do one on the. But as with most car components, there are subtleties involved. Web tightening wheel locks or lug nuts seems like one of the simplest things you will ever do to your car. B) using a ratchet and 19mm deep socket tighten lug nuts in a star pattern (shown in. This pattern helps keep the wheel. Web lug nuts must be installed in an alternating pattern, commonly referred to as a star pattern. Web tighten one lug nut, then move to the one across from it in a crisscross or star pattern. Measure your pattern correctly the first time! Web a lug nut tightening pattern, also known as a “star pattern,” is the order in which you should tighten the lug nuts on a wheel. Web 4.0 19 ratings. Web one is the main part that is steel, and the other is a chrome, aluminum, or stainless steel cap that fits on top and makes it look pretty. Time takes its toll on your. Web how to measure a wheel bolt pattern. This pattern is essential for evenly. This diagram will show you what order to tighten your lug nuts. This ensures even clamping force. Web use the lug nut wrench to tighten the lug nuts as much as you can.Steel Star Spline Drive Lug Nut for Aftermarket Wheels 12x1.5

How to Troubleshoot a Car that Nose Dives When Braking YourMechanic

How to Diagnose and Repair Noisy Brakes YourMechanic Advice

Steel Star Spline Drive Lug Nut for Aftermarket Wheels 12x1.25

star pattern tightening lug nuts 5 bolt wheel ASMR YouTube

NASCAR NextGen Wheels The Scientific Argument for a Single Lug

Locking lug nut key replacement — Ricks Free Auto Repair Advice Ricks

How to Tighten Lug Nuts YourMechanic Advice

Guide Replacing a 20072013 GMC Sierra 1500 Wheel Bearing & Hub

How to Remove the Wheels from Your Vehicle YourMechanic Advice

This Ensures A Uniform Distribution Of Load Across The Wheel Mounting Surface.

Refer To The Torque Chart And Use A Torque Stick If Available.

Web C) Remove The Factory Lug Nuts.

Web Start To Screw On The Lug Nuts By Hand And Note If There Is Any Resistance.

Related Post: